We modernize your industrial scales

Is your scale technically outdated? We can make it future-proof again.

A modernization at VISSER is more than just a repair – it is a targeted upgrade of your existing weighing technology. We only replace the components that are required for long-term functionality and reliability. This means that your tried-and-tested scales are retained, but are brought up to the latest technical standard.

Modernization for industrial and commercial scales – practical & precise

Typical measures:

- Replacement of obsolete load cells or indicator terminals

- Integration of digital interfaces (e.g. USB, Ethernet, fieldbus)

- Retrofitting self-service systems for truck scales

- Addition of monitoring elements for monitoring weighing processes

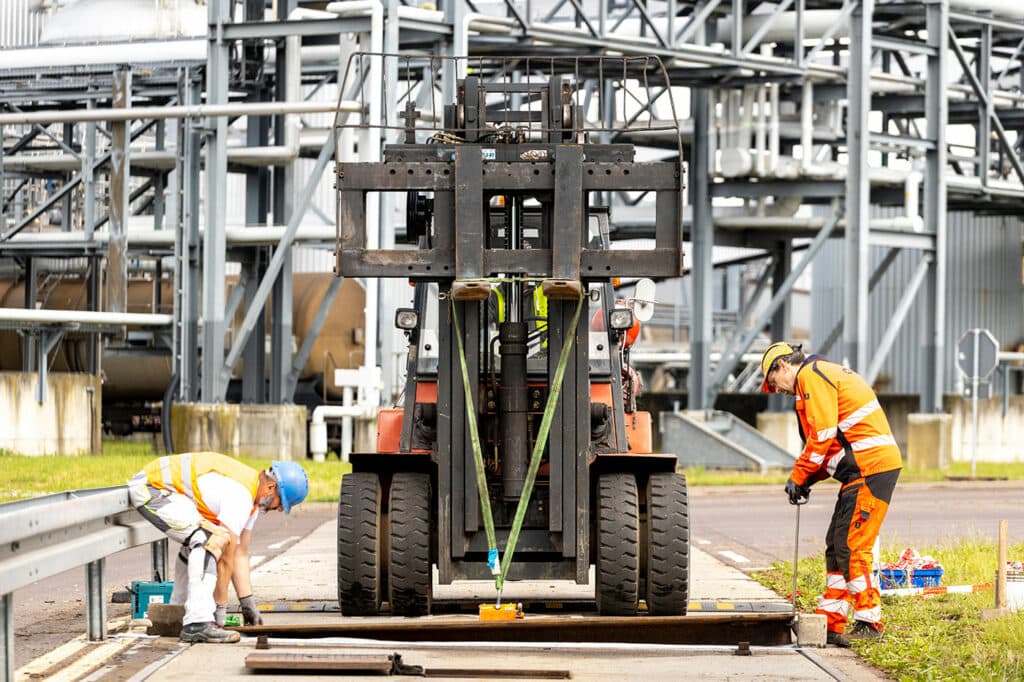

- Mechanical conversion: new bearings, bridges or force transmission within existing foundations

The result: fewer faults, greater operational reliability – and often lower follow-up costs compared to a new purchase.

Conversion of mechanical scales to electronic

Many older scales still work purely mechanically – reliably, but with limited functionality and interfaces. We convert these into electromechanical systems in accordance with the applicable type approval:

- Installation of digital load cells with defined force transmission

- Adaptation of the load lever mechanism to the required calibration error limits

- Testing & documentation in accordance with measurement and calibration law

This turns an analog scale into a modern, verifiable measuring system – perfectly tailored to your requirements.

Why VISSER?

Advice, planning and implementation – all from a single source

Duisburg location – directly there for you

Decades of experience in converting and retrofitting complex weighing systems

Close cooperation with manufacturers, test laboratories and calibration offices

Modernization of truck scales –

Recognize opportunities, know the limits

Modernization brings your truck scales up to the latest technical standards – but can also present challenges, depending on the situation. At VISSER, we help you to find the right balance between technical upgrading and economic efficiency.

Advantages of a truck scale modernization

✔ More precise measured values

Modern load cells, digital displays and improved force transmission increase the accuracy and reliability of your weighing processes – important for legal-for-trade applications.

✔ Faster processes

Automated self-service terminals, digital interfaces or integrated traffic light systems speed up throughput and save time in day-to-day operations.

✔ IT connection & transparency

Modern systems can be integrated into your existing software environment – from ERP to logistics platforms. This allows you to keep an eye on your weighing processes in real time.

Possible limits and considerations

⚠ Investment costs

Particularly in the case of comprehensive modernization, acquisition costs must be weighed against the remaining service life of the old appliance. In some cases, a new purchase may be more economical.

⚠ Integration & compatibility

Old IT systems or special process requirements can make integration difficult. We check in advance whether your system landscape is compatible with the planned modernization.

⚠ Maintenance effort

Technically upgraded systems come with additional components – and require specialized maintenance or updates if necessary.

Our conclusion with VISSER

Modernization pays off – if it fits the process. Whether it’s a targeted upgrade or a complete renovation, we support you with expertise, experience and an open view of your overall situation. Let us weigh up together what is the best solution for you in the long term.

Request a non-binding consultation now – we look forward to hearing from you.